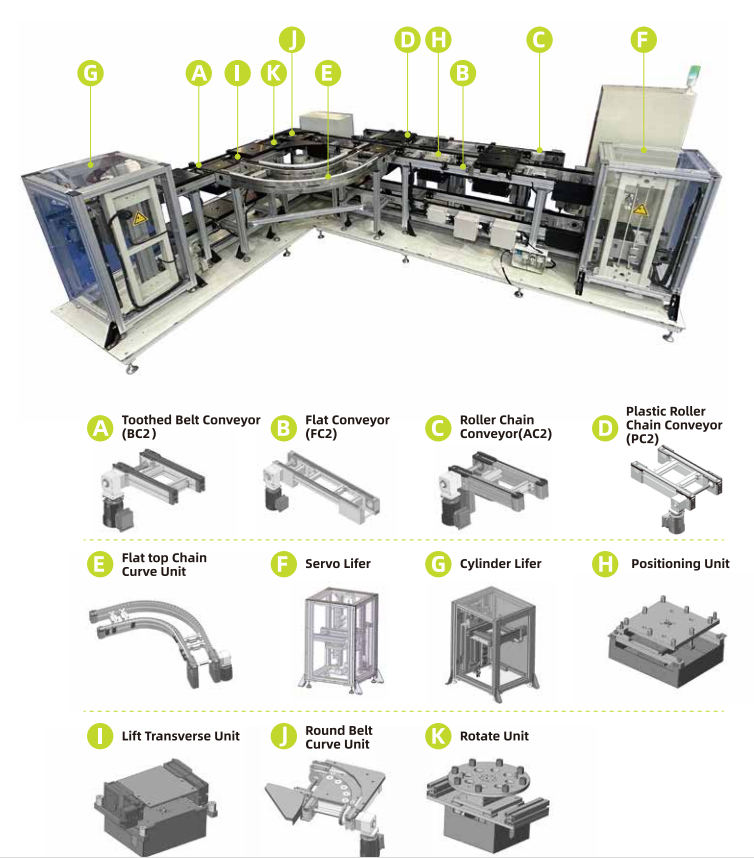

Modular Design: The Vitrans system has an easily adaptable nature, allowing it to blend into any automated environment while meeting various production requirements based on its modular set-up. Precision Handling: Accurately handle, position and rotate materials along assembly lines or other industrial settings facilitating smooth flow of work and better management of goods used in the process. Versatile Solutions: With flat belt conveyors, chain conveyors or even plastic chain options among others being available configurations can be customized according to specific needs within different sectors served by Vitrans. Efficient Pallet Handling: This system is designed around effective pallet management so as to improve material transfer within a given production area. Competitive Pricing: When it comes to cost, Vitrans ensures affordability without compromising quality hence becoming more economical than some major brands such as Bosch, Dorner or Flexlink which are also our competitors in terms of pricing for premium automation products like this one offered by us at Vitrans. Quality Assurance: Our commitment towards providing high standards items makes them stand out from counterparts produced elsewhere; this is evident when comparing their qualities against those made by firms like Bosch, Dorner or Flexlink which are among other similar companies known globally due to their consistent production and reliable systems over time but none can be compared with what we guarantee here at Vitrans where we never disappoint clients who come looking only for the best things. Transform Your Automation Journey: The Vitrans Pallet Conveyor System represents innovation, versatility and cost-effectiveness synonymous with various applications ranging from home-based setups all to complex industrialized areas thus people should start using Vitrans if they want automation solutions that will save them money. You can’t go wrong with Vitrans! "conveyor""conveyors""belt conveyor""chain conveyor""pallet conveyor""conveyor system" Vitrans Automation Equipment Co.,Ltd , https://www.vitrans-automatic.com

Â

Items

Unit

HBT0804-JZC200

Max. Output

m³/h

8

Max Theoretical Output

m³/h

10

Max Exit Pressure

MPa

4

Type of Distribution Valve

Â

SÂ valve

Concrete Cylinder Bore x Stroke

mm

140×800

Main Oil Cylinder Bore / Stroke

mm

Φ90/Φ65×800

Oil Tank Capacity

L

100

Outlet Diameter

mm

Φ150

Inner Diameter of Delivery Pipe

mm

Φ125

Diesel Engine Model

Â

CY1115(YANMAR)

Diesel Engine Power

KW

30

Water Pump Motor Control

Â

Electromagnetic Clutch

Max Aggregate Size

mm

30

Towing Speed

Km/h

≤8

Max Horizontal Conveying Distance

M

100

Max Vertical Conveying Distance

M

30

Mixer Model

Â

JZC200

Input Volume

L

300

Output Volume

L

200

Drum Diameter

mm

1000

Drum Rotation Speed

R/m

15

Charge Hopper Load Up Time

S

5

Charge Hopper Unload Down Time

S

4

Tread Distance

mm

2100

Outline Dimension

mm

4120×2100×2600

Weight

Kg

3000

Container Needed

20GP

1Â

Performance Characteristics:

2. Mixing and pumping can be operated by one worker, saving labors.

3. Control box adopts PLC programme, stable, reliable and long service life.

4. Charging, mixing, rotating and pumping are all controlled by hydraulic system, high automation and simple operation.

5. Driven by single cylinder, YANMAR diesel engine, low fuel consumption, simple maintenance, high reliability, service and maintenance all over the world.

6. The water pump adopts electromagnetic clutch and the time relay control, automatic timing water, without water pressure.

7. Welding type glasses plate, high hardness cutting ring, repairable and low cost;

8. Independent cooling system, high cooling efficiency;

9. Manual lubrication system, fuel efficient and reliable;

10. Dual purpose folding bracket, when unfolded it forms manual feeding ramp, after folding it becomes to be bracket;

11. Especially apply for small building under 3 floors, casting concrete in place;

12. One 20ft container can load two sets of the machine, saving shipping cost;

13. Adopts stealth aircraft polyhedron appearance, fashionable and artistic;

14. The mixer and the pumping unit are respectively performed by two independent sets of hydraulic system without mutual interference;

15. The mixer and the pumping unit with fast connection apart, can work independently, it is a dual-purpose machine.

Vitrans Automated Production Line pallet Conveyor system

Professional customized production line conveyor and assembly line conveyor, automated, modular, make your production and andassembly more efficient and upgrade your production line easier. No matter what the product is, it will increase your production line capacity.

Automation Redefined: Vitrans Automated Conveyor Systems

Vitrans Pallet Conveyor Systems are leading the way in automated production with top efficiency and accuracy achieved through the use of current technology. This versatile modular system is necessary for cutting-edge manufacturing across industries.

Main Features:

Vitrans Advantage:

8m3/H Mini Concrete Mixer Pump for Concrete Mixing Plant

8m3/H Mini Concrete Mixer Pump for Concrete Mixing Plant

HBT0804-JZC200 8m3/h Mini Concrete Mixer Pump, Small Concrete Mixer Pump, Portable Concrete Mixer Pump

1. With the functions of mixing and pumping combined into one machine, HBT0804-JZC200 concrete mixer pump can move easily, flexible, small size, light weight, and strong mobility.